Franklin Barbecue Pit Franklin Barbecue

$ 5.150,00 $ 1.287,50

Every Franklin Barbecue Pit is made by hand in the good ol’ USofA. As a result, each of our handcrafted pits has its own quirks and characteristics making it truly one of a kind! These differences in cosmetic attributes do not affect the performance of the pit (or the tasty meals it will surely produce). Cook chamber and firebox door gaps may move around a bit from manufacturing, welding and cooking. During our quality control process, any element that does not fall within our range of tolerance is addressed before final approval. The skill of our welders combined with the natural elements of the steel work together to create YOUR pit, there won’t be another one like it!

– 625 lbs.

– 81″ long and 81″ high from ground to top of smokestack

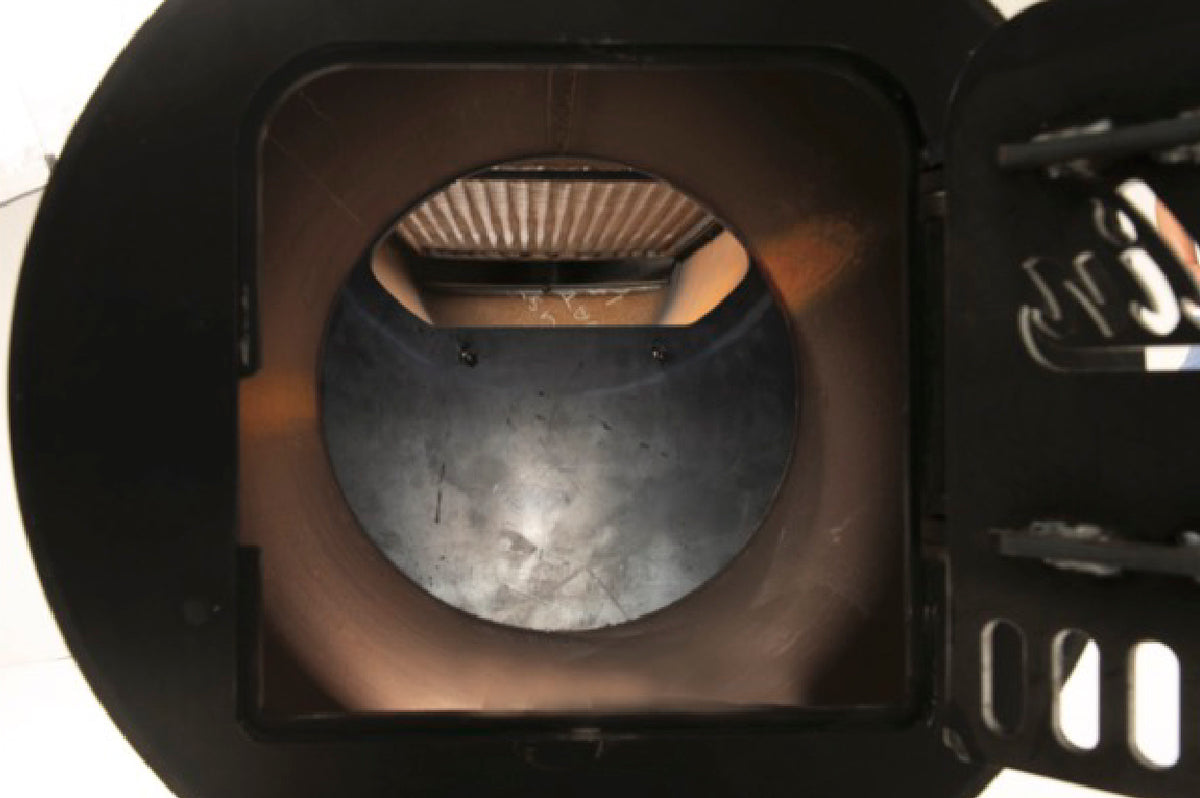

– 42″ cook chamber

– 1/4″ thick rolled American-made steel cook chamber and inner firebox (firebox is double-walled with air gap)

– Ships in one crate

Your pit comes with…

– Custom Tel-Tru Thermometer

– Grease Bucket

– Water Pan

– Removable Steel Cooking Grate

– Bolt-on Smokestack

– Pit Badge with Unique Body Number Riveted to the Bottom Shelf

– 5″ Casters (2 Stationary at Firebox End, 2 Swiveling at Smokestack End

– Owner’s Manual

The pit is approximately 625 lbs, and despite being on casters, can be difficult to maneuver. It’s best to move the pit with an extra set of hands (or two) into your desired area where it can remain in that spot. It’s best to pick a solid and level location that can support the weight of your pit (ie. concrete pad or pavers).

The raw steel pit will need to be regularly seasoned on the inside and the outside with food grade oil (we like flaxseed oil or rendered fat from leftover trimmings). Seasoning the pit with food grade oil will protect it from rusting, especially if you live in a humid place or let the pit come into contact with water. Basically, take care of it like you would your grandma’s heirloom cast iron pans.

Fast Delivery and Professional Packaging

We offer a broad range of shipping options thanks to our long-standing partnerships with UPS, FedEx and DHL. Our warehouse staff are highly trained and will package your items in accordance with our exact and precise specifications. Your products will be subjected to an exhaustive examination before they will be safely packaged prior to being delivered. Each day, we ship to thousands of customers in different countries. This is an indication of our determination to become the biggest online retailer in the world. The distribution centers and warehouses distribution are in Europe and the USA.

Orders that include more than one item are given processing time for each item.

Prior to shipment, all purchased items will be thoroughly examined. Today, the majority orders will be delivered within 48 hours. The delivery time should be between 3-7 days.

Returns

Stock is dynamic. It is not managed entirely by us, as we have multiple parties such as the factory and our storage. The actual stock can fluctuate at any time. Please understand it may happen that your order will be out of stock when your order has been made.

Our policy lasts 30 days. If you don't receive your product within the 30 days period, we are not able to issue a refund or an exchange.

Your item should be in its original packaging and not be used. It must also be returned in its original packaging.

Related products

Gas Griddle